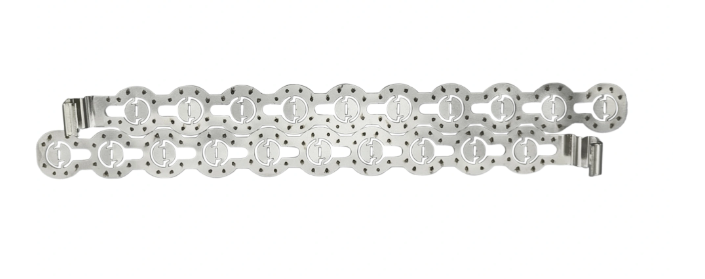

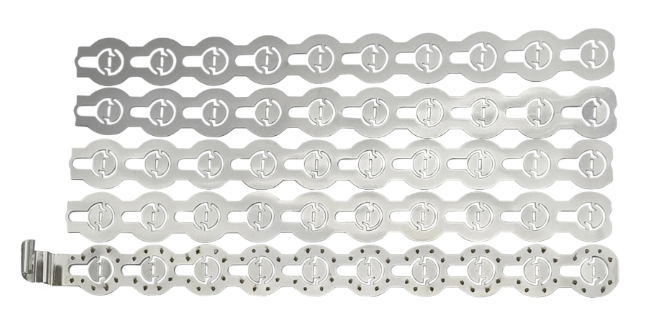

| Material |

0.2mm Pure Nickel and 1.0mm Copper |

| Dimension |

0.1, 0.127, 0.15, 0.2, or Custom,The thickness and dimensions can be met what customers required. |

| Package |

According the customers requirement, such as bulk bag . |

| Physical properties |

Spot welding is good, the resistance is lower, battery discharge time longer, the battery spot welding is stronger. |

| Advantage |

The ease of machining and low electric resistance of this material make it best suited for such products as battery terminals. |

| Technical support |

With Japanese Sodick, complete mold (more than 2000 sets of battery industry hardware mold), and can open mold independently. |

| Product high stability |

material quality is stability and reliability. |

| Functions |

this product is mainly used in Traction Battery Pack, Electric Car Battery Pack Connector, etc. |

1.High Conductivity: Copper nickel welding strips exhibit excellent electrical conductivity, ensuring efficient transmission of electrical currents.

2.Corrosion Resistance: The combination of copper and nickel provides inherent corrosion resistance, enhancing the durability and longevity of the welding strips.

3.Ductility:Copper nickel strips are ductile, allowing for flexibility and ease of shaping during the welding process,accommodating various applications.

4.Good Weldability: Copper nickel is known for its good weldability, facilitating reliable and secure welding processes for

different applications.

5.Thermal Conductivity: These strips possess good thermal conductivity, aiding in effective heat dissipation and contributing to the stability of electrical systems.

6.Suitability for Battery Packs: Copper nickel welding strips are commonly used in battery packs due to their reliable

conductivity and durability, especially in high-power applications.

7.Long Service Life: The robust nature of copper nickel welding strips contributes to a long service life, ensuring sustained performance over time.

8.Cost-Effective: Copper nickel is often more cost-effective than alternative materials with comparable conductivity, providing a cost-efficient solution for various industries.

9.Recyclability: Both copper and nickel are highly recyclable materials, aligning with sustainable practices and environmental considerations.