Product Description:Flexible busbars are made from copper foil with thicknesses ranging from 0.1 to 1mm. Produced through welding, stamping, plating (tin or nickel), forming, and insulation (PVC dipping or PE heat shrink tubing), they offer excellent conductivity, flexibility, easy installation, and space-saving design. These features make them ideal for EV battery packs, new energy power distribution, UPS systems, and charging stations.

Bus Bar Performance:

Conductivity: 57%

Tension strength: ≥500N

Insulation flame retardant: UL94V-0.

Insulation temperature resistance: -45℃ to 150℃

Resistance to corrosion: It can pass 240H salt spray test in neutral environment.

Temperature rise: Depends on cross section area. RHI can provide temperature rise reports for all products.

Bending Testing: Bend 10000 times in 15 radian angle without breakage or fracture.

Details:

| Material: |

T2 ( E-CU58, CU-ETP, C11000, C1100 )

TU2 ( OF-CU, CU-OFE, CU-OF, C10100, C1011 )

Aluminum (1060 )

Copper Clad Aluminum

Or other materials as customer’s request. |

| Insulation: |

PE and PVC

- PE : Withstand Voltage 2700V AC, Working Temperature -40℃ to 125℃,

Flame Retardant UL224 VW-1. Used for rigid & flexible busbar, but it can

not be used for special-shaped products.

- PVC (Dipping): Withstand Voltage 3500V AC, Working Temperature -40℃

to 125℃, Flame Retardant UL94V-0. Used for rigid & flexible busbar, and

can be used for special-shaped products.

|

| Finish: |

Tin plating, nickel plating, silver plating or customized. |

| Packing: |

Blister and wooden box packing to avoild bus bar broken or deformed. |

| Quotation time: |

1-3 days after receiving drawings. |

| Certificates: |

ISO45001, ISO14001, IATF16949 |

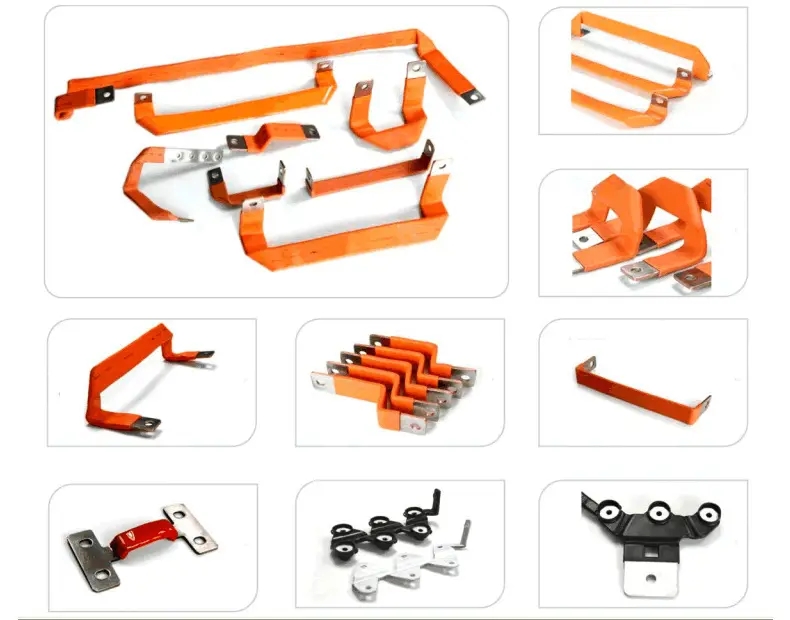

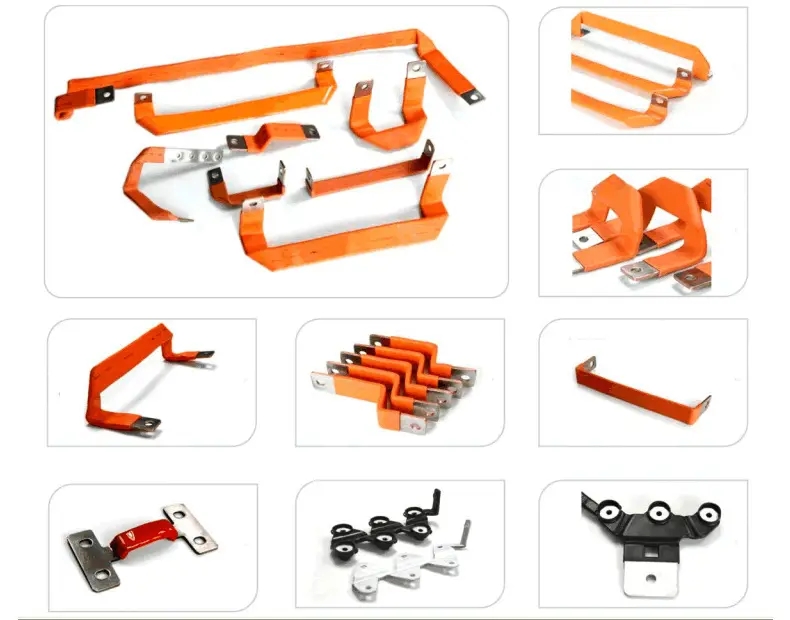

Product Gallery:

Advantages:

- Press bonded laminations improve electrical conductivity.

- The feature of flexible enable us to make flexible busbars in more types.

- Flexible busbar can be made with longer length.

- Flexible laminate busbar is not easy to be broken after thousands times of bending.

- Graduated laminates increase power efficiency

Applications:

- New energy electric vehicle battery pack connections

- Wind and solar power systems

- High voltage distribution

- Circuit breakers, generators, and prefabricated power network conductors

- Expansion joints

- Transformers

- Machine connections