What quality requirement need for nickel sheet/ nickel strip?

News 2024-07-21 111

Spot Welding is a very important process during the battery pack assemble. The performance of the welding is not only affected by spot welding machine, the electrodes,the parameter, and also the welding material, like nickel sheet, copper nickel busabr,etc.

So what quality requirement need for battery pack connector? And how do we control them?

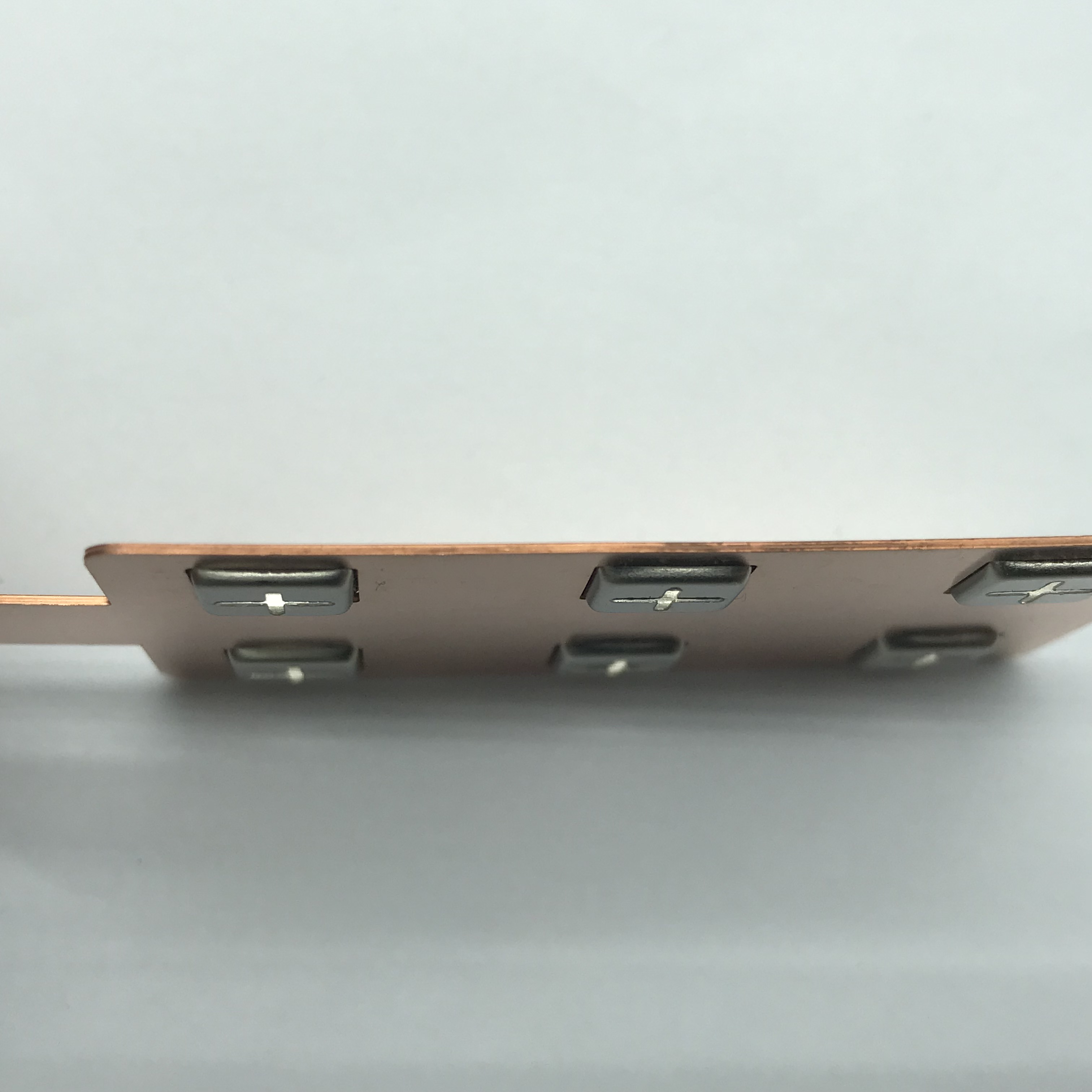

Within tolerance, No burrs, clean surface, Flatness, is the basic requirement for the nickel sheet for spot welding

Tolerance:

This is the standard requirement for products.

Burrs:

As we know, the products made through stamping and laser cutting have burrs on the cut side, normally need to control it within 0.05mm, but if too high, the problem would be : the burrs would scrap the pvc shrink and make the short of the battery; the burrs leave the distance between the nickel sheet and the cell, it would cause the fake welding; the distance between the nickel sheet and the cell cause the resistance bigger, the cell is easier to be heat up.

This is the standard requirement for products.

Burrs:

As we know, the products made through stamping and laser cutting have burrs on the cut side, normally need to control it within 0.05mm, but if too high, the problem would be : the burrs would scrap the pvc shrink and make the short of the battery; the burrs leave the distance between the nickel sheet and the cell, it would cause the fake welding; the distance between the nickel sheet and the cell cause the resistance bigger, the cell is easier to be heat up.

Clean surface:

Normally means the oils and scrap on the surface, it would cause the big welding spark during the welding, also cause the resistance bigger, the current it can hold is smaller.

Normally means the oils and scrap on the surface, it would cause the big welding spark during the welding, also cause the resistance bigger, the current it can hold is smaller.

Flatness:

If the nickel tab is not flat, especially the welding area, the all area must touch with the cell, if there any space, it also would cost the fake welding, which means the weld is loose, not very tight. And also casue the resistance bigger.

If the nickel tab is not flat, especially the welding area, the all area must touch with the cell, if there any space, it also would cost the fake welding, which means the weld is loose, not very tight. And also casue the resistance bigger.

Flatness:

If the nickel tab is not flat, especially the welding area, the all area must touch with the cell, if there any space, it also would cost the fake welding, which means the weld is loose, not very tight. And also casue the resistance bigger.

How do we control these quality defect?

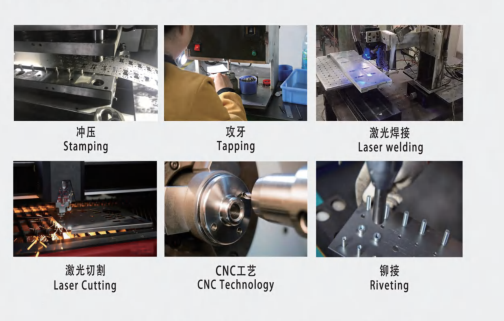

The stamping machine we use is all high quality and precision machine from Taiwan or Japan, such as Duobi.

The mould we made with the material of tungsten steel and process with WEDM-LS, so the mould is more strong and the tolerance it can control is more precise.

The raw material is already been clean before stamping, and we use the dry-punch technology to avoid adding the oil during the production.

How do we inspect our products?

All the incoming material need to be measured the tolerance of the thickness.

During the production, we have first inspection, the self inspection by operation in certain time, and the patrol inspection by IPQC, to see the tolerance of the dimension, the flatness, the surface condition, etc

After the production,our operator to check those again , for those bigger size, we check them one by one.

During packing, our QC check again in random bags.

Good spot welding effect, lower internal resistance, longer discharge time of the battery pack, and firm spot welding of the battery

Suitable for new energy vehicles, Ni-MH Ni-Cd batteries, lithium-ion batteries, mobile phone batteries, notebook batteries, mobile power supplies, etc.

Good spot welding effect, lower internal resistance, longer discharge time of the battery pack, and firm spot welding of the battery

Suitable for new energy vehicles, Ni-MH Ni-Cd batteries, lithium-ion batteries, mobile phone batteries, notebook batteries, mobile power supplies, etc.